4/18/2023

Liquid Artistry: JEO Designs a Water Curtain

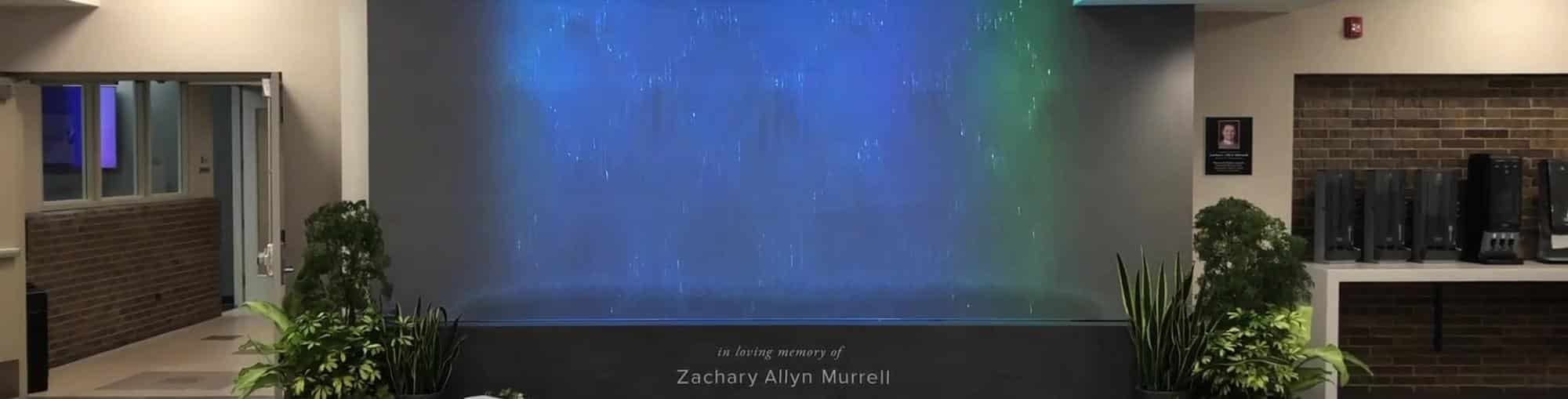

JEO’s structural team excels in bridges, culverts, and other infrastructure-based designs. However, they recently branched out to use their expertise in a new way. Working with JEO’s architects, they designed a water curtain for Western Iowa Tech Community College in Sioux City, Iowa.

As the impressive centerpiece in the Robert H. Kiser Building, the water curtain stands 10 feet tall, 16 feet wide, and five feet deep, with a 2.5-foot-deep basin. Within stainless steel housing, the curtain constantly recycles nearly 550 gallons of water, transforming it into a falling, thin aquatic curtain that appears to change patterns and colors. Behind the scenes, a computer controls the curtain’s 200 water ports, dictating when they open, how long they remain open, and when they close, thus producing varying patterns—even pictures. This same computer alters the appearance of the water’s color as well.

While watching the finished product may be mesmerizing, designing the curtain involved deliberate problem-solving and coordination from the JEO team. The physical location of the curtain was determined by the college from the beginning, but calculating a way to position it into that space was the team’s first task. They created an initial design, then imported it into a modeling program to create a three-dimensional model of the curtain. This 3D model provided finite details, allowed the team to see how structural pieces would fit into the space, and gave them the ability to make real-time design adjustments as needed.

In addition to the various patterns, the college wanted to be able to showcase their logo in the water. In order to see the entire picture as the water fell, the curtain needed to be a particular—yet unknown—height. Once the team finalized the measurement, it was found to be taller than the area’s existing ceiling. To accommodate the height and support the curtain’s cantilevered upper holding tank, the team cut into the ceiling space, tapped into the roof trusses, and added steel columns. This upper area also houses the bulk of the curtain’s mechanisms, so a venting system was also added to prevent the ports and computer equipment from overheating.

Another key factor to determine involved water volume. The team ascertained how much water the entire feature would use during operation, then utilized that figure to calculate how large to make the specially fabricated holding basin at the base of the curtain. It had to be large enough to hold all the water should electricity be cut off, which would result in all the water falling into the basin from the ceiling’s upper holding tank and related piping.

All throughout the process, the team knew the final product needed to operate quietly and not splash onto the highly trafficked tile floor. To meet these goals, they worked closely with steel fabricators to develop a floating anti-splash pad that not only eliminated almost all splash, but also floated with the basin’s fluctuating water depth and also reduced noise. This proved to be a win, win, win.

This project was designed, fabricated, and installed on an accelerated timeline in order to be unveiled at an already-scheduled spring campus event. Construction began in early December 2021, and the project made its public debut in late May 2022—right on time.

Click here to see a video of the water curtain in action.